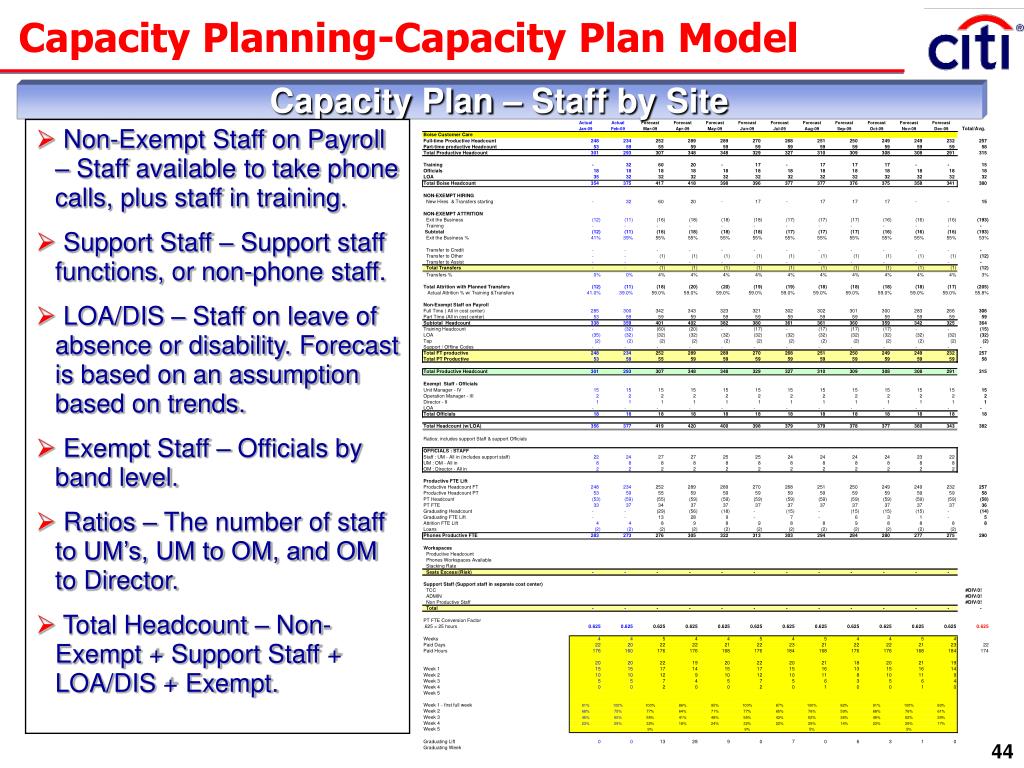

And the 'chase' capacityPurpose of Capacity Plan Provide the purpose of the capacity plan For example Capacity planning is an important part of infrastructure and deployment planning A capacity plan supports the goal of optimum, and cost effective, provisioning of organizational resources and services by matching them to business demandsCloud computing services, airline seat capacity and fastfood restaurants 3 HUMAN CAPACITY Human capacity includes those organizations which sell specific skills of their team members

Capacity Planning Organization System Examples Definition System Long Term Capacity Planning

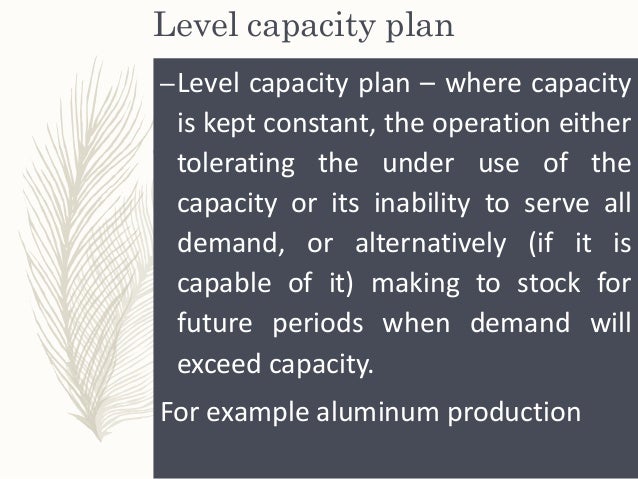

Level capacity plan example

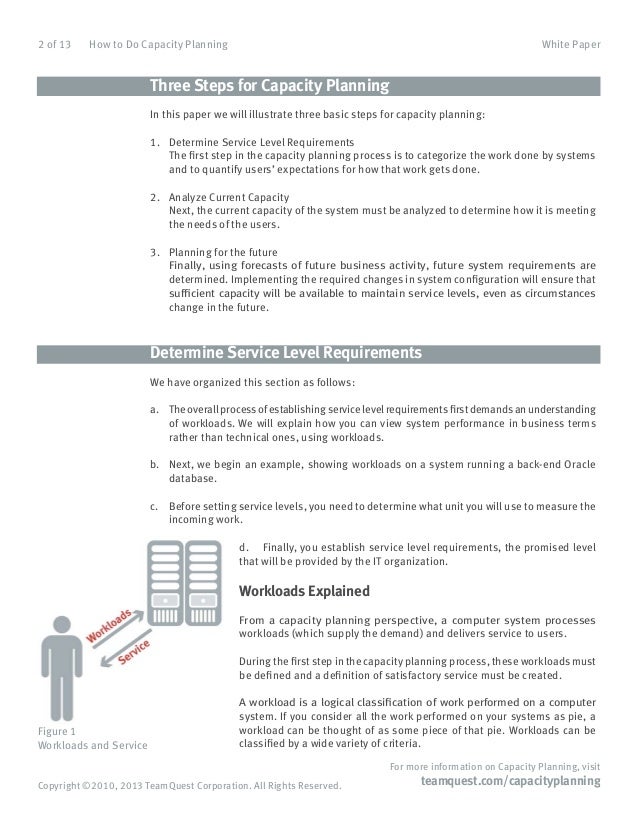

Level capacity plan example-Capacity planning and Katana Katana is an allinone smart manufacturing solution that gives you the tools to help you perform your resource capacity plan, along with Inventory management Production management Sales orders Integration features to manage your entire business, all from one dashboardSelecting a capacity alternative most suited to achieving strategic mission 17 THREE STEPS OF CAPACITY PLANNING 18 Determine Service Level Requirements 19 The first step on the capacity planning process is to categorize the work done by systems and to quantify users' expectation for how the work gets down Define workloads 21

Aggregate Capacity Planning Pdf Free Download

The idea here is that a level schedule is used during consistent periods and the chase strategy is used during months with fluctuating demand This can be helpful in seasonal business For example, a company that made Halloween chocolates, may maintain a level schedule for 9 months of the year and then use a chase strategy during the weeksA product capacity plan ensures you have enough products or ingredients for your deliverables For a florist, this would be flowers, vases, and cards For a pool maintenance company, this would be things like chlorine that are required to do the job 2 Workforce capacity planningAggregate capacity is the total amount of capacity required or available to carry out a function It also tells about the 3 best strategies for aggregate planningThey are level strategy, Chase strategy and hybrid strategy

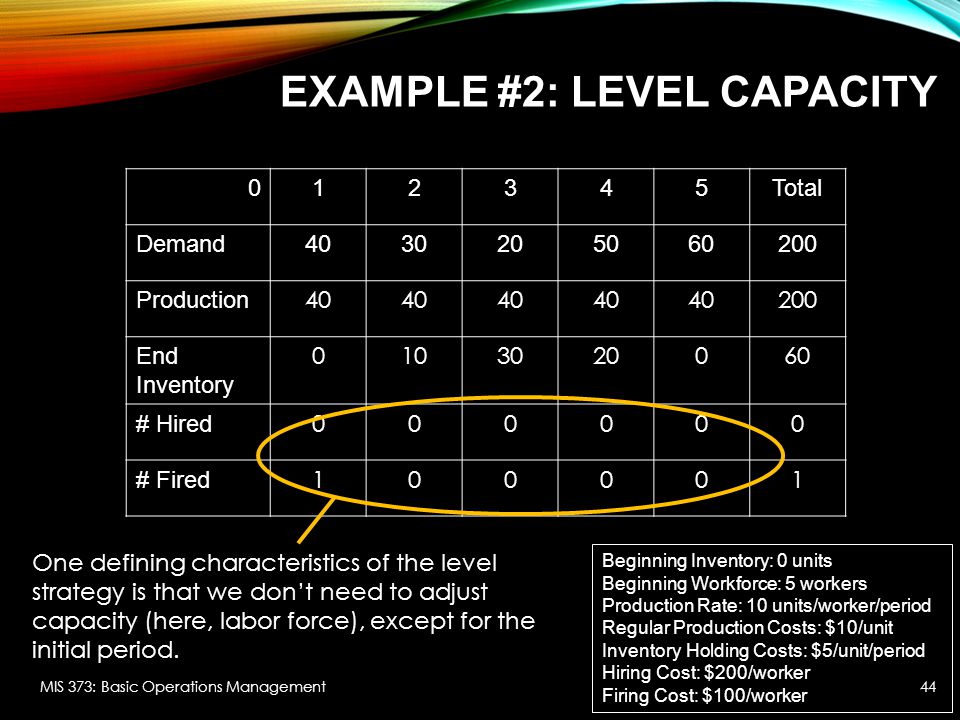

1234 Available capacity per weekLevel Capacity Plan The inventory size is varied keeping the workforce size and utilization of work constant The number of workers ( working size) is kept constant throughout the time period under consideration During months of low demand the excess units required over the units produced are taken from the inventoryExplain about the level capacity strategy Level capacity strategy The organisation produces or manufactures at a constant rate of output avoiding any changes or fluctuations within customer demand levels This frequently implies stockpiling or higher holdings of inventory while customer demand levels reduce

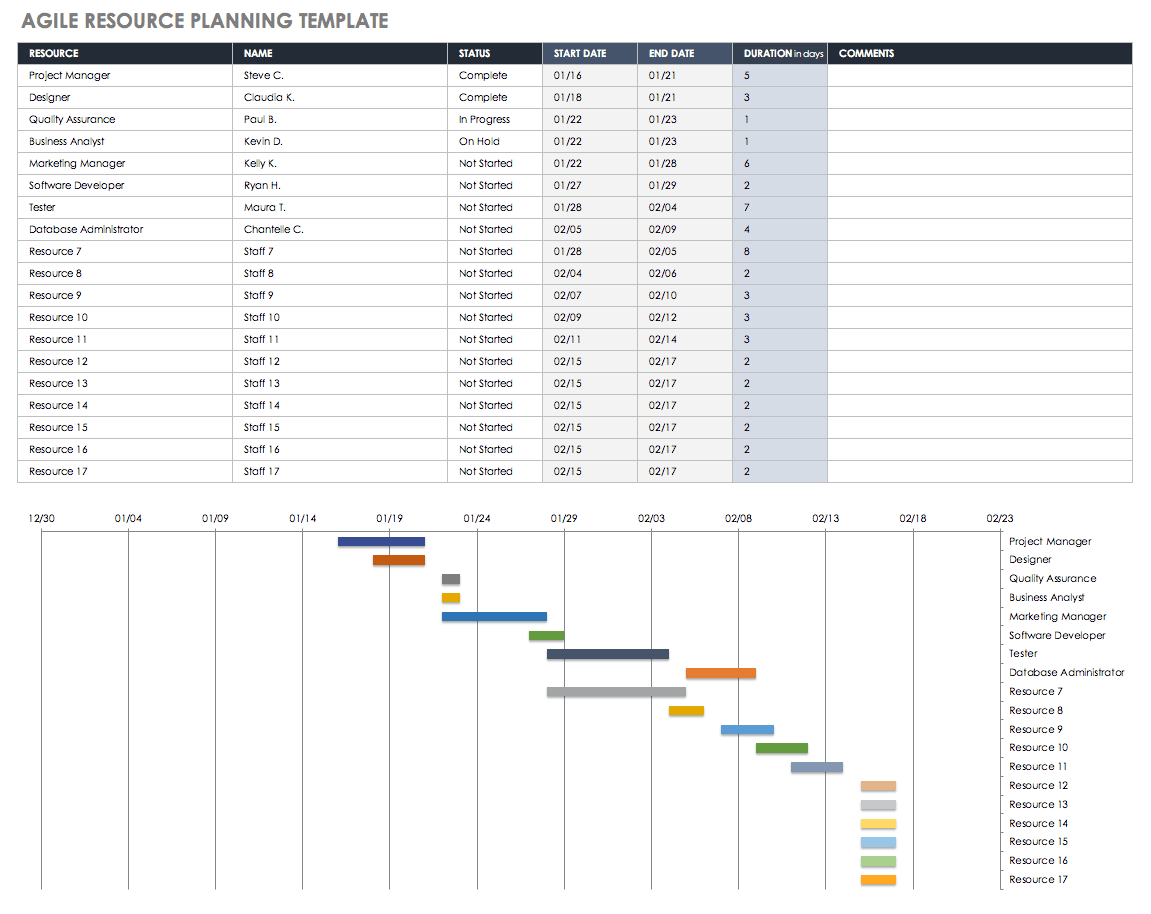

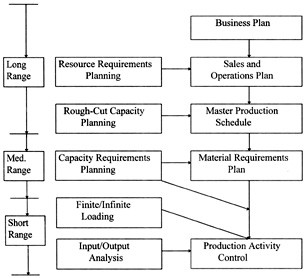

Benefits of Resource Capacity Planner Template Excel spreadsheets are useful in many ways such as;Slack, Chambers and Johnston, 08) Identified capacity strategies are the 'level' capacity strategy with a uniform output level;Longterm capacity planning may evolve when shortterm changes in capacity are insufficient For example, if the firm's addition of a third shift to its current twoshift plan still does not produce enough output, and subcontracting arrangements cannot be made, one feasible alternative is to add capital equipment and modify the layout of the

Checklist Capacity Plan It Process Wiki

Workclout 3 Case Studies Examples Of Capacity Planning

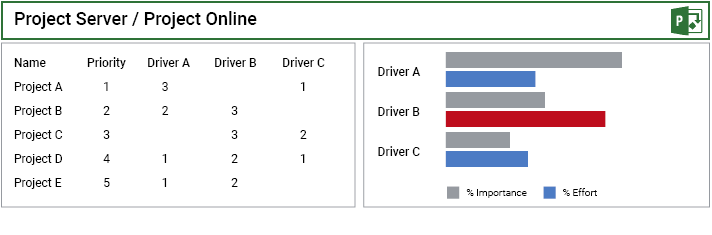

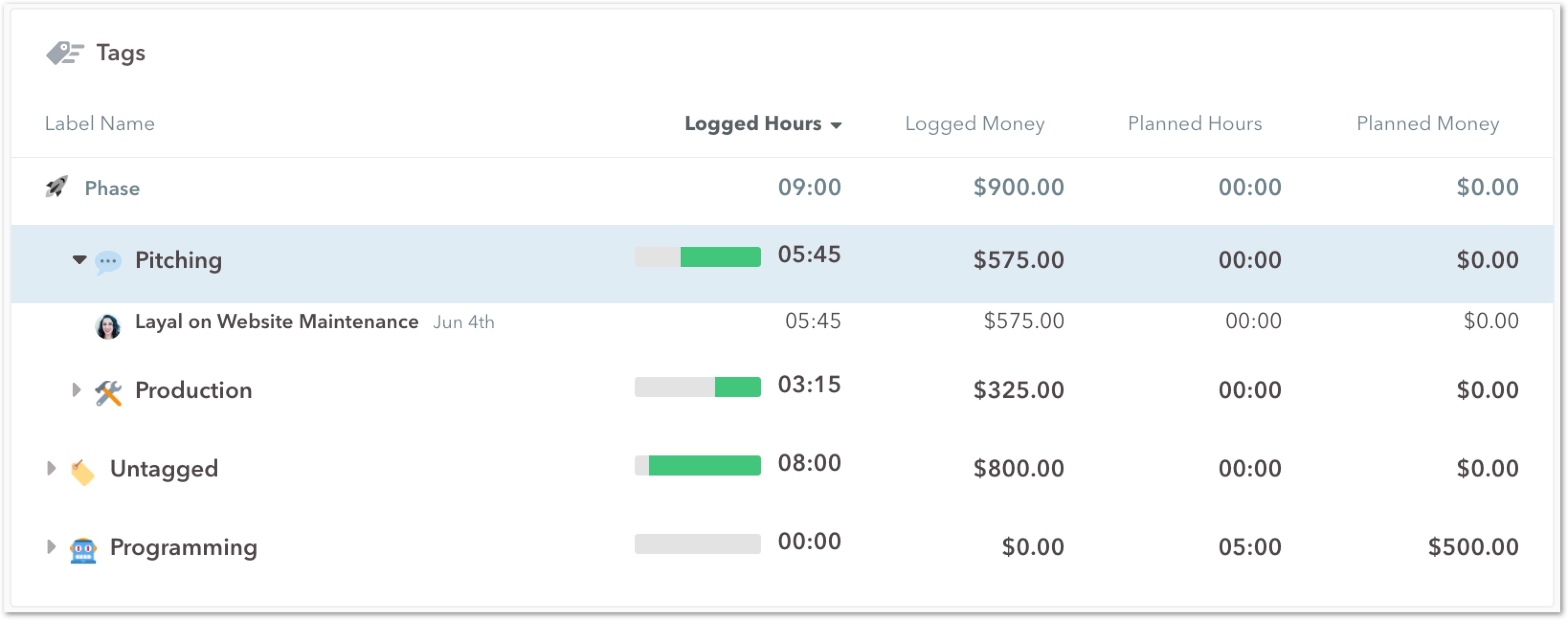

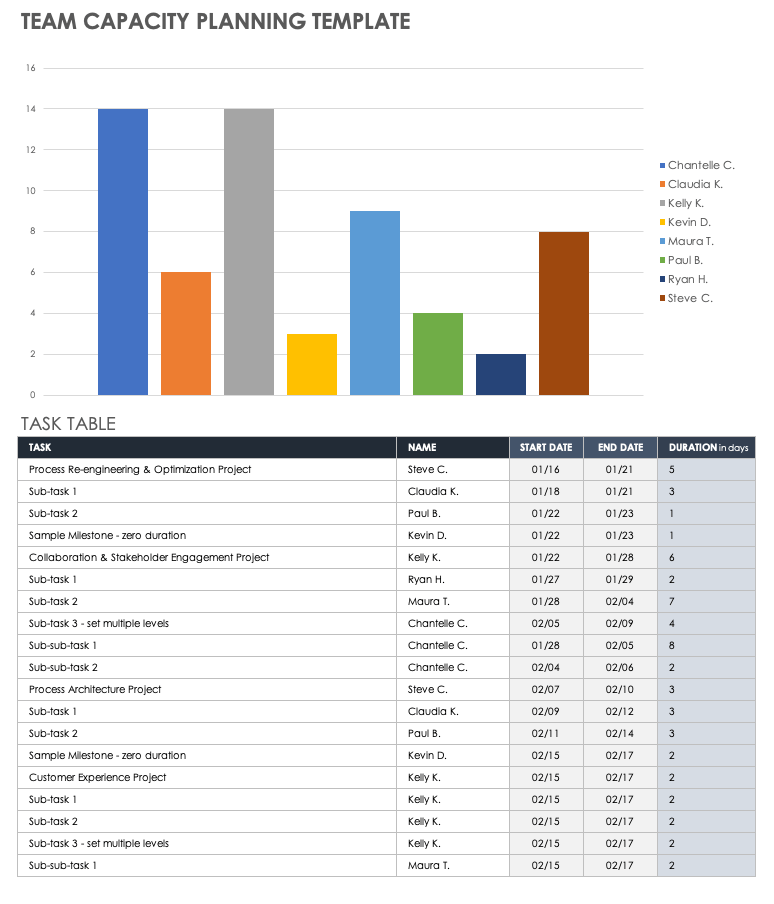

Resource level Capacity vs Demand Clearly two resources Developer 3 and Developer 2 do not have enough capacity to complete the tasks assigned to them Meanwhile, 3 other resources have a lot of additional hours available but not utilized In the next page of the dashboard, you can see the charts of Capacity vs Demand in Hours⌧ Assembly 1000* 1500*22 600*25 = min = 1133,33 hr ⌧ Inspection 1000*2 1500*2 600*2,4 = 6440 min = 107,33 hr etc ⌧ available capacity per week is 10 hr for the assembly work center and 110 hours for the inspection station;SAMPLE – SURGE PLAN – "CODE YELLOW" DEFINITION This is a general Surge Plan and is based on two assumptions 1 Very specific activities would be initiated along with these guidelines dependent upon the nature of the disaster (CBRNEChemical,

The Goal Of Resource Capacity Management

Free Resource Planning Templates Smartsheet

Sample Capacity Building Plan DRAFT Rev 10 4 Guiding Principles During the Change It is important for Organization ABC personnel to follow these principles as it implements the actions in this Plan 1 Focus on what is needed to change, not on the way it has always been done before 21 Develop production plan 2 Check implications for inventory/backlog plan 3 If necessary, adjust production plan 4 Check against resource plan and availability 5 If necessary, adjust production plan 6 Recheck against inventory/backlog and resources 7 Continue (go toThis can provide the right level of service to customers at the right time Some examples are;

What Is Resource Leveling Techniques And Examples Asana

1

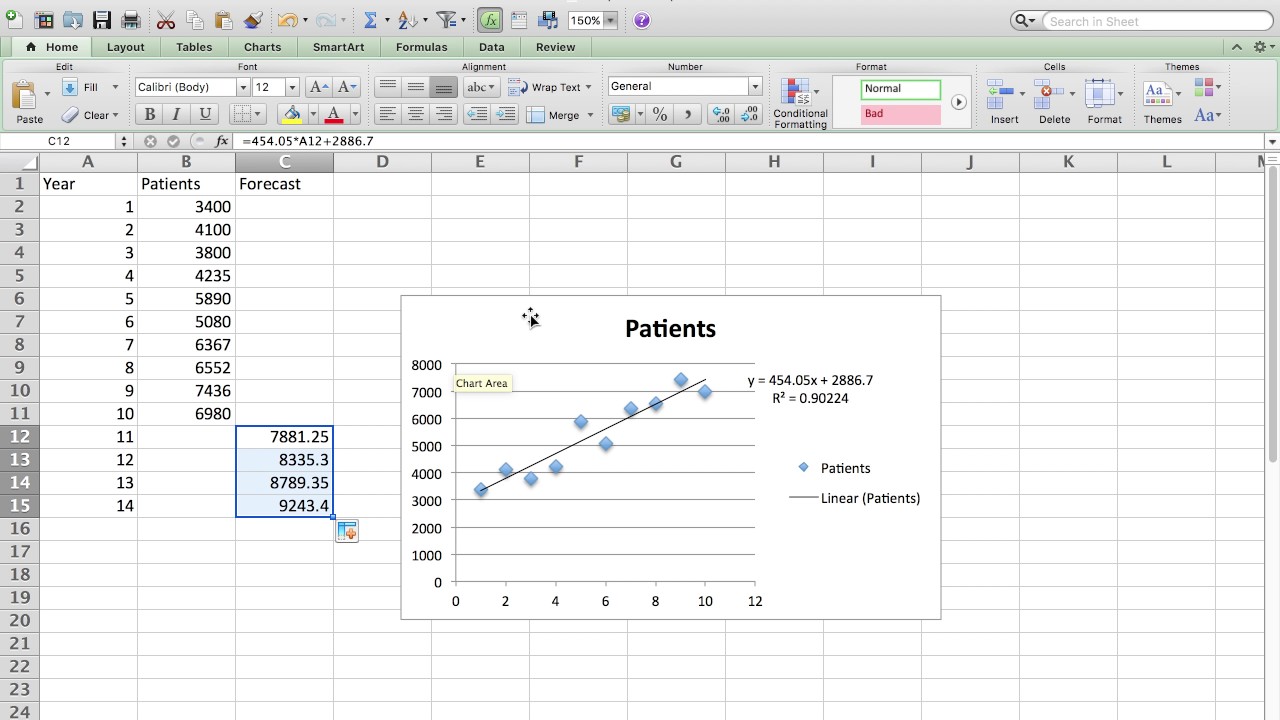

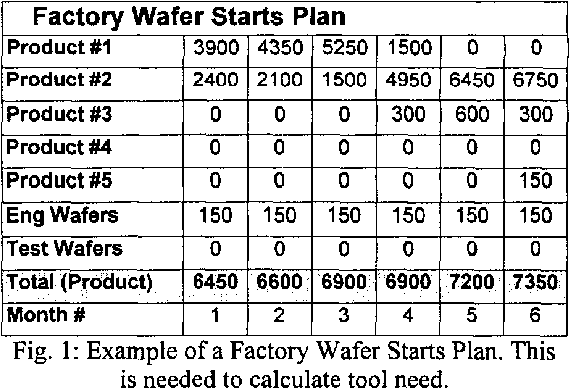

Further, the key outcome of using a production capacity template excel spreadsheet is to keep the product inventory to a minimum level even fulfilling the customer demands So, good capacity planning for production results in a positive response to the fluctuation in product demand in different seasons over the product lifecycleHere is a very basic example of what a high level capacity plan looks like Model Tips Create excel tables that allow flexibility and automation For example, set up a formula so when any of the influencers change up or down, the capacity plan updates on its own (This allows you to leverage "what if" scenarios)Bill of capacity (min) ⌧ weekly capacity requirements?

Capacity Planning Template Explore 7 Tips For Effective Planning Project Management Templates

Capacity Planning And Control

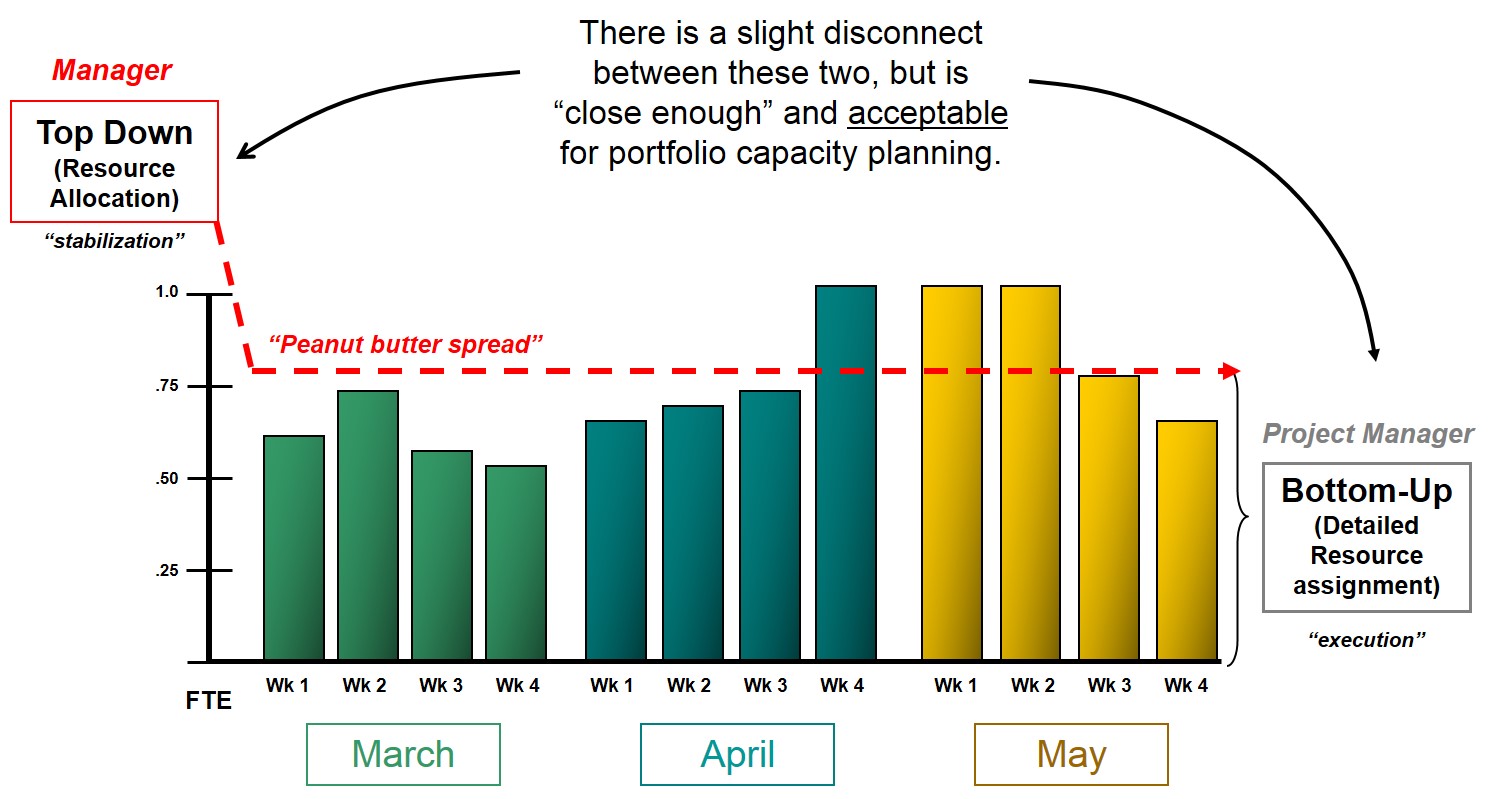

To keep your capacity planning simple, you need to analyze your capacity plan at the team or skill level and not by analyzing individual resources Which means for example comparing how many project managers you need for your projects vs how many you currently haveAn example of level capacity management could be the first step of the production of salt by evaporation (in Italy there is one industry like this in Salina) In hot countries, salt is produced by allowing the sun to evaporate sea water in shallow pools or 'pans';Resource planning template excel – free download resource planning template excel helps to plan resource capacity planning utilization and allocation you can track and to monitor the bandwidth of the team and manage your resource more effectively templates for staff capacity planner spreadsheet excel hi the staff capacity template is a great

Capacity Planning By Essaysupply Issuu

The Alternative Capacity Plans Level Capacity Plan Ignore The Fluctuations And Course Hero

This point This capacity check looks at all resource capacities, not just bottlenecks The result of this process is a finalized material requirements plan The bottom level is where planning ends and execution takes over The material requirements plan results inBusiness Capacity Management The capacity of teams, business capabilities and processes This can include human resources, equipment, infrastructure, facilities and technology For example, an operations team plans the resources required to boost production byCapacity requirement planning forms part of the operational stage of the planning process and works in conjunction with a manufacturing requirement planning (MRP) system A detailed capacity requirement plan provides an operational level overview for the production cell and assists the operations manager with identifying all of the elements

Capacity Planning Everything You Need To Know Clicktime

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Capacity is often measured in hours available to be worked by employees And in this context, "planning" is the act of scheduling employee hours against a fixed or expected amount of work Example A company has 10 employees Each employee works 40Level capacity strategy The demand for any product is never constant It may change due to various reasons An operations manager has to plan in advance about the demand of the product He or she may have to use some strategies to meet this uneven and everchanging demand pattern These include pure strategies and strategy which uses aAs these operations often have complex multilevel BOMs, capacity planning must include planning for subprocesses required to produce components or assemblies for final construction An example of this would be a production facility where single serve meal or snack kits are produced

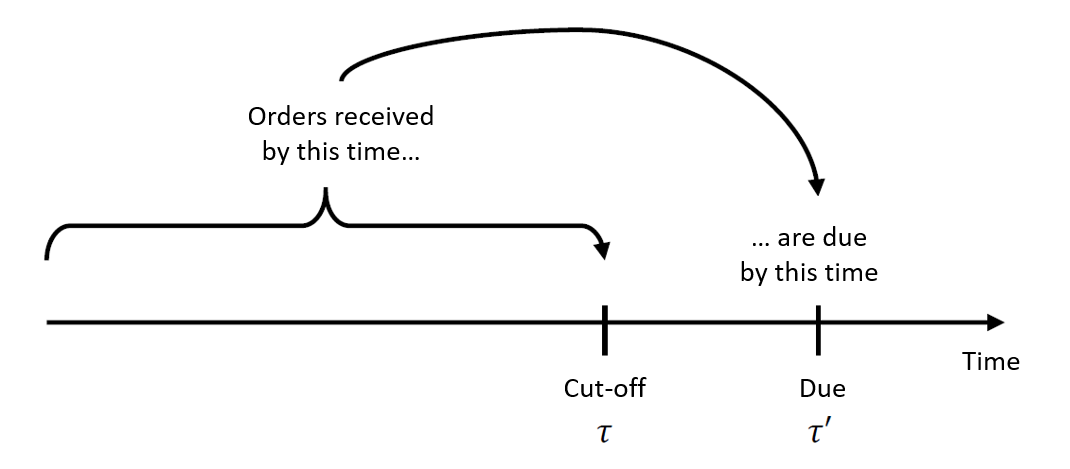

Ifl Research All Current Research Projects Performance Analysis And Capacity Planning For Stochastic Systems With Cut Off Service Levels

Project And Task Assignment Clarizen Success

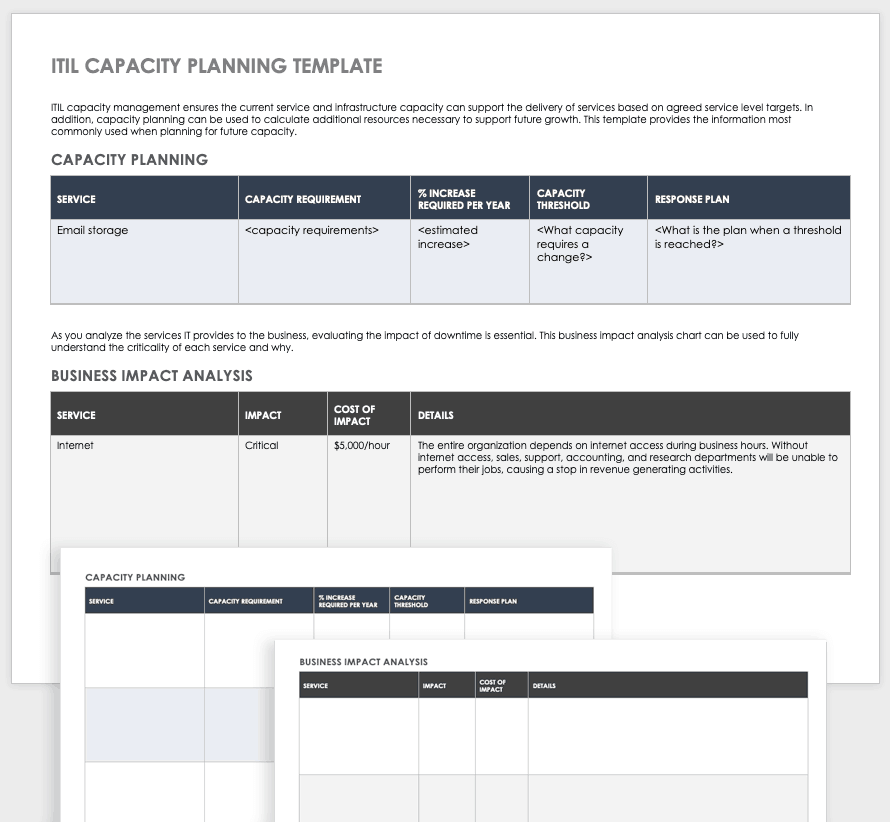

The Capacity Plan is used to manage the resources required to deliver IT services The plan contains scenarios for different predictions of business demand, and options with cost estimates to deliver the agreed service level targetsEffective capacity is the optimum production level under predefined job and workschedules, normal machine breakdown, maintenance, etc Medium Term Capacity The strategic capacity planning undertaken by organization for 2 to 3 years of a time frame is referred to as medium term capacity planning3 Examples of Production Capacity John Spacey, Production capacity is the volume of products or services that can be delivered by the operational resources of an organization Resources include factors such as land, labor, facilities, infrastructure and machines The following are illustrative examples of production capacity

Skills Capacity Planning As New Projects Arrive Innate Management

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

The steps are in order Evaporation, Wash, Centrifugation, Grinding, Drying, Sack, Packaging, Shipping9 HighLevel Project Plan Examples – PDF Highlevel planning is focusing on establishing your project's requirements and deliverables, and then tracking them over time Every time you estimate a new project and assign resources to it, you are actually creating a highlevel project planUp to12%cash backGenerally, these options fall into two "pure strategies" – a chase strategy and a level strategy Under the chase strategy, production is varied as demand varies With the level strategy, production remains at a constant level in spite of demand variations (00) LEVEL STRATEGY FOR CAPACITY PLANNING In Swamidass PM (eds

How To Do Capacity Planning Youtube

Capacity Planning Template Explore 7 Tips For Effective Planning Project Management Templates

It streamlines the resources management process It saves time It displays a summary sheet for a quick overview It saves money for getting the licensee of costly software It uses a pretty familiar and easily available excel spreadsheet toolSmoothing plan is best suited to situations where inventory carrying costs are low We will now present a simple example that illustrates the two extreme plans and a plan that results from solving a linear model Data Initial conditions 300 workers, 500 units of inventory atCapacity Plan Template Version Xx This Capacity Plan is an integral part of infrastructure and deployment planning It supports the goal of Service Level Agreements (SLAs), utilization reports, capacity modeling, and workload forecasts

Capacity Planning Example

Aggregate Capacity Planning Pdf Free Download

Prologue to Capacity Management and Availability Management (CAM) The capacity and Availability management field involves setting up and oversight of capacity and availability at a reasonable cost with proficient utilization of resources Various levels perform this process in an organization across allied services Download This Template It includes and servesA period's planned quantity of output is equal to that period's expected demand Level capacity strategy When an organization adopts the level capacity strategy then it manufactures at a constant output rate It does not consider any fluctuation or change in the level of demand(For example, if an employee worked a 40hour week but only billed clients for hours, then his employee utilization would be 50%) Using the Capacity Planning Template In the Summary section, you'll see your Total Project Demand, Effective Capacity, Resource Deficiency, and Recommended Action

Capacity Planning Pdf Resource Strategic Planning

Capacity Planning 3 Methods How To Implement Them Optimoroute

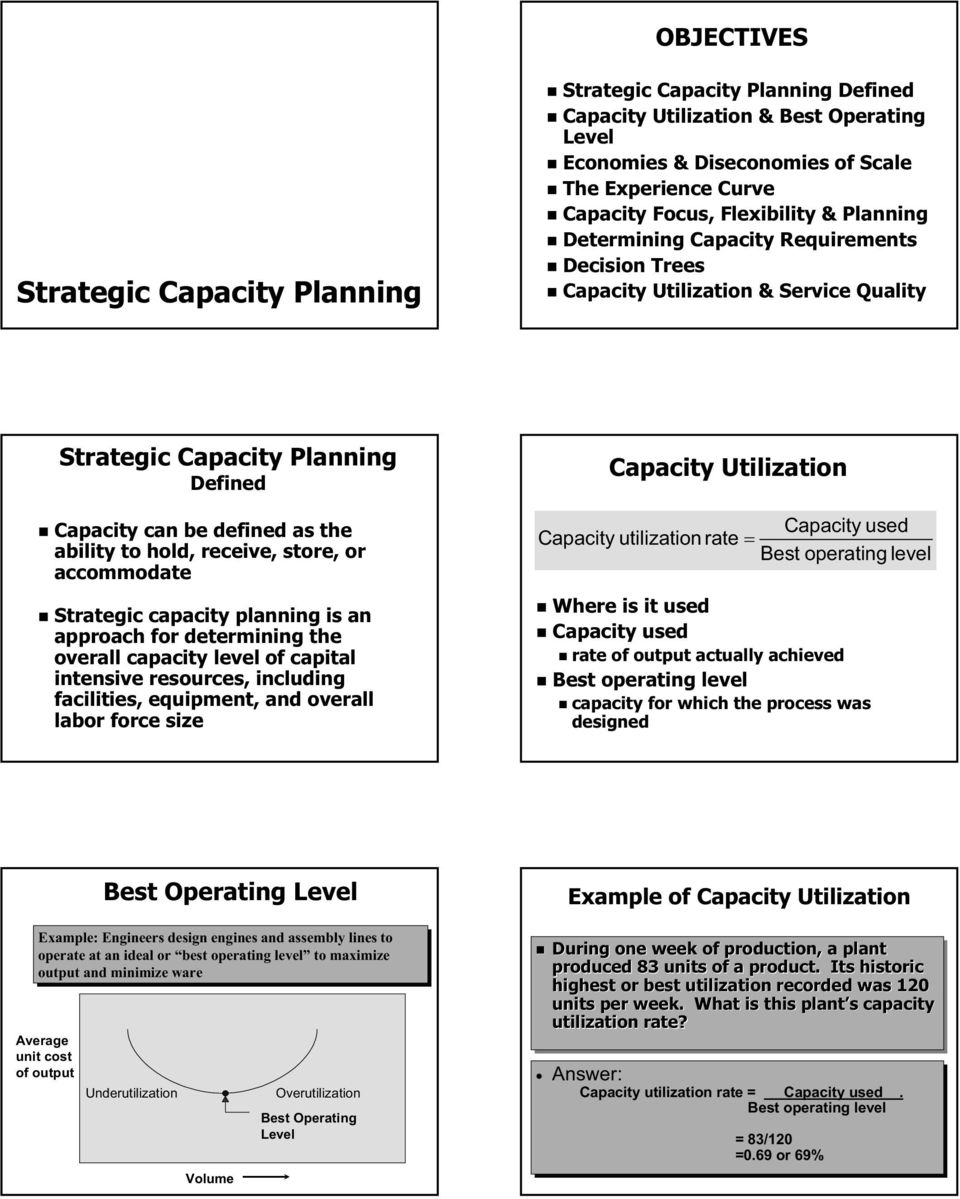

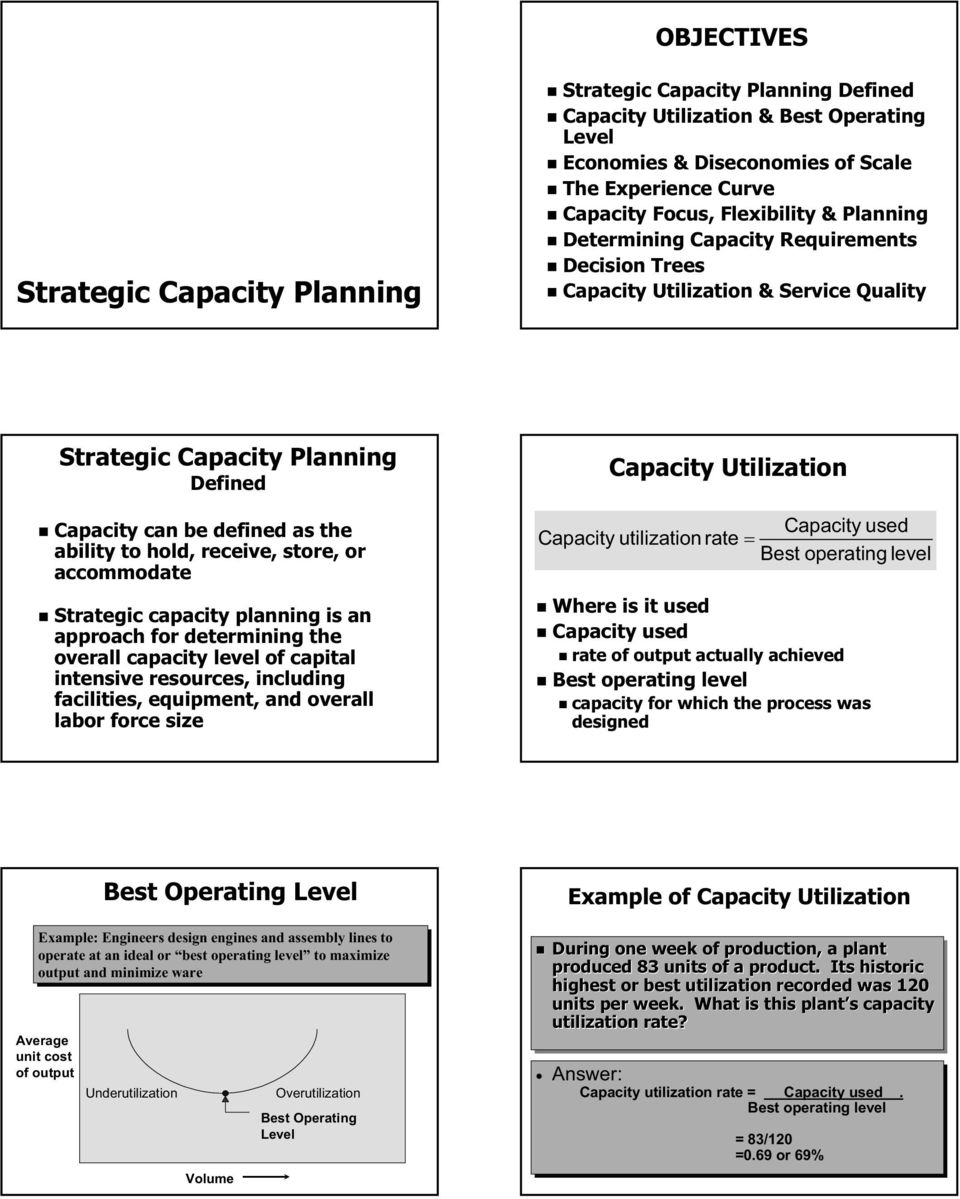

Use break even analysis to evaluate capacity alternatives This module examines how important strategic capacity planning is for products and services The overall objective of strategic capacity planning is to reach an optimal level where production capabilities meet demand Capacity needs include equipment, space, and employee skillsWhat is a level capacity plan?Capacity utilization is the proportion of available capacity that is utilized and is quantified by the ratio of actual output to capacity output (Nelson, 00;

Maintenance Capacity Planning Ppt Video Online Download

27 Free Printable Production Capacity Planning Template Xls By Production Capacity Planning Template Xls Cards Design Templates

1 Capacity Development Working Group (WG) Terms of Reference (June 10) 2 Organizational Capacity Assessment Sheet (version 2) 3 Individual Capacity Assessment Sheet (version 1 and version 2) 4 Sample of Programme Design Matrix (PDM) 5 Sample of Plan of Operation (PO) 6 Evaluation Sheet for final PresentationThe two balancing acts in capacity planning Cost and capacity In IT capacity planning, there are two dimensions in a balancing act The first dimension is the balance between costs and capacityIn other words, ensuring that the processing capacities satisfy the business requirements at justifiable costs and will be used as efficiently as possibleCapacity Planning It's pprove/cancel projects

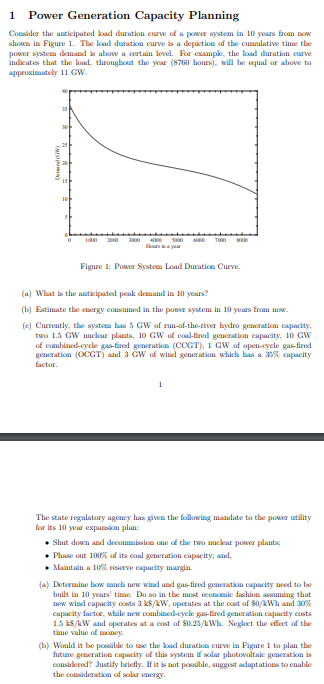

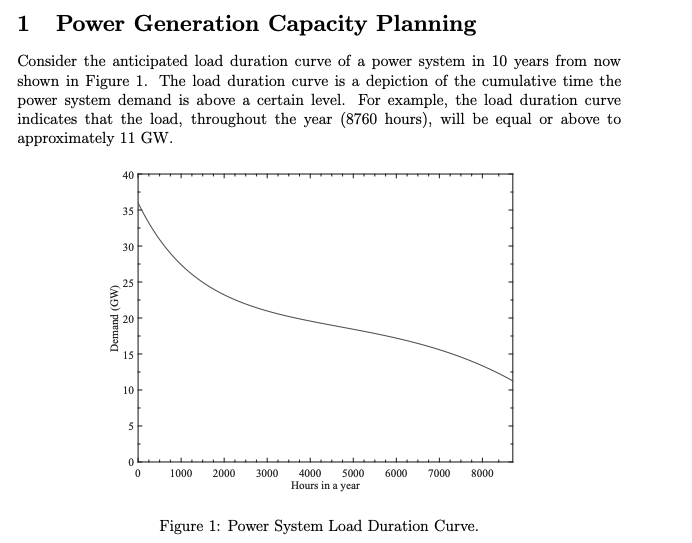

1 Power Generation Capacity Planning Consider The Chegg Com

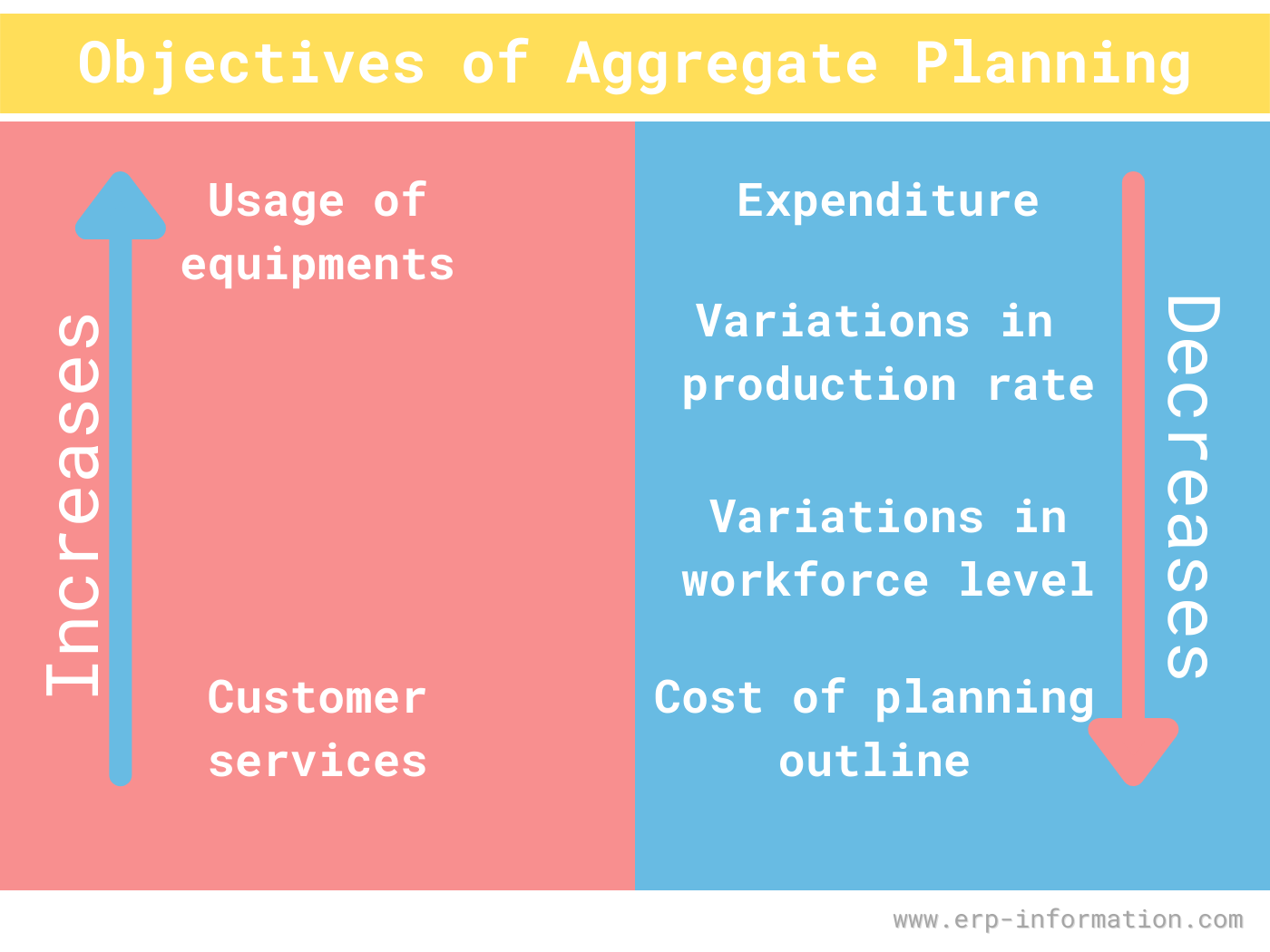

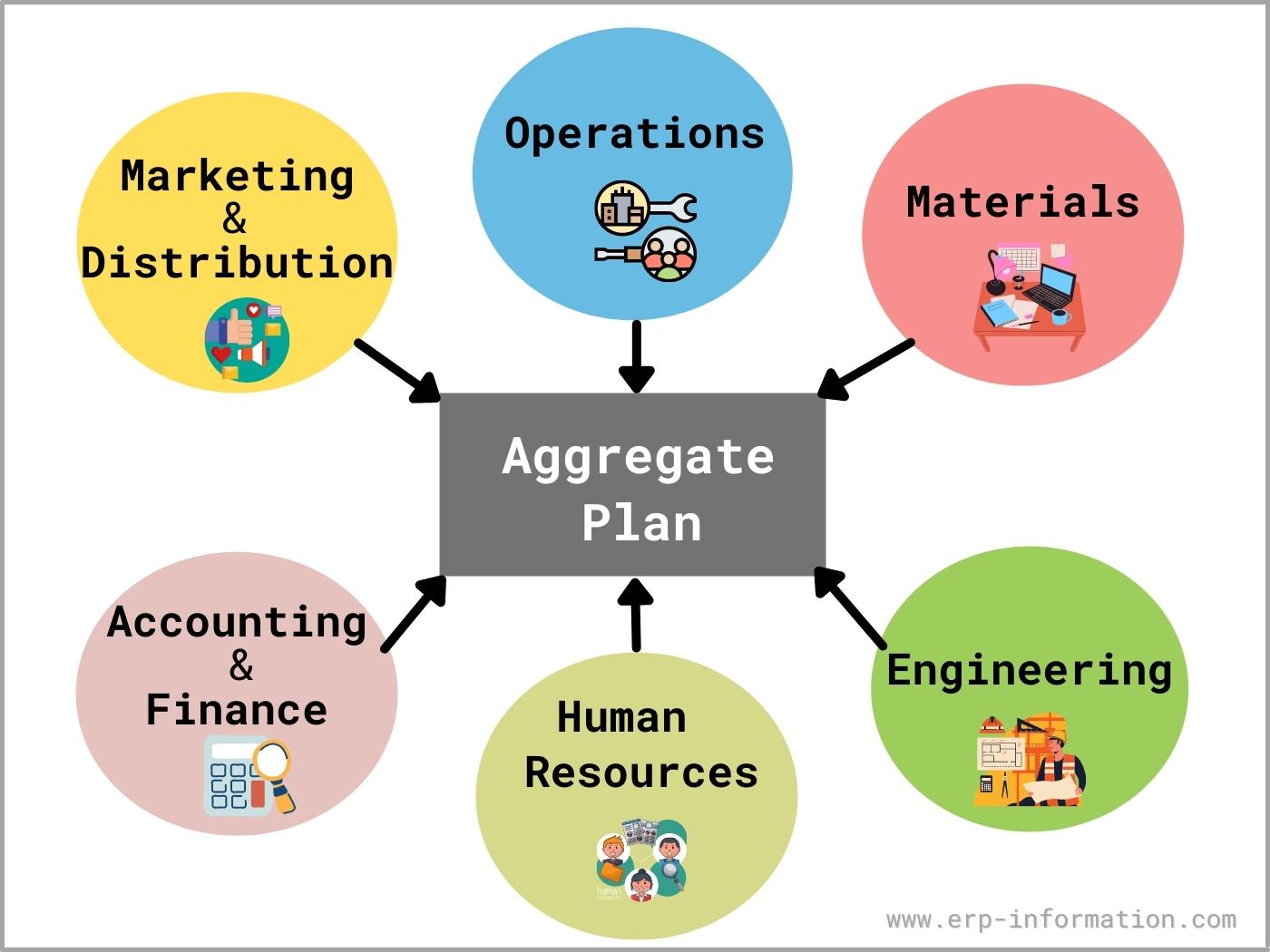

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

Capacity Planning Everything You Need To Know Clicktime

Ppt Capacity Planning Powerpoint Presentation Free Download Id

Capacity Planning Process Youtube

1 Power Generation Capacity Planning Consider The Chegg Com

Resource And Capacity Management

4 Steps To Strategic Human Resource Planning Lucidchart

Capacity Plan Template Ms Office Templates Forms Checklists For Ms Office And Apple Iwork

Capacity Planning In Project Management 4 Vital Success Factors Update 21

Pdf Capacity Planning For Diabetes Management Indian Example

Capacity Planning And Management Case Study Example Topics And Well Written Essays 1250 Words

Capacity Planning In Project Management 4 Vital Success Factors Update 21

Doc Capacity Planning Richa Verma Academia Edu

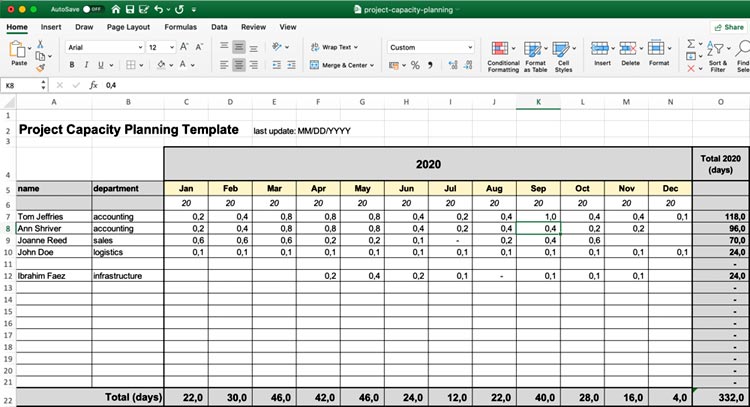

Project Capacity Planning Template This Excel Sheets Saves You Hours

Capacity Plan Template Technical Writing Tools

How To Do Capacity Planning

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Capacity Planning Template Explore 7 Tips For Effective Planning Project Management Templates

Capacity Planning Organization System Examples Definition System Long Term Capacity Planning

Master Production Schedule

Capacity Planning What It Is How To Do It Well

How Is Yield Management Implemented In Airline Industry Ayat Saleh

Capacity Planning And Control Chapter 11 What Is

Capacity Building Wikipedia

Capacity Planning 3 Methods How To Implement Them Optimoroute

Capacity Planningcapacity Planning Long Rangelong Range Springerlink

Level Capacity Plan Ppt Powerpoint Presentation Pictures Background Cpb Presentation Graphics Presentation Powerpoint Example Slide Templates

Capacity Planning Basics Part 1 Of 2 Wfmanagement

Capacity Plan Template Ms Word Templates Forms Checklists For Ms Office And Apple Iwork

Strategic Capacity Planning Capacity Utilization

Aggregate Planning Chapter 11 Aggregate Planning Aggregate Planning

Aggregate Capacity Planning Pdf Free Download

1

Capacity Planning Everything You Need To Know Opensense Labs

08 Capacity Management Lecture Note Bus Be 375 Bus Be I Core Iu Studocu

Mcse Prep Hardware Capacity Planning Intense School

1

Could This Be The Easiest Way To Do Team Capacity Planning Kendis

Pdf An Approach To Capacity Planning Of Distribution Warehouses For X Firm Semantic Scholar

Capacity Planning 3 Methods How To Implement Them Optimoroute

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Iteration Planning Scaled Agile Framework

5 Best Resource Capacity Planning Template Excel

Capacity Utilization Definition Example And Economic Significance

Capacity Planning Sample Template Agile Digest

Capacity Planning Template Free Download

5 Steps To Create A Tech Support Capacity Plan The Operations Blog

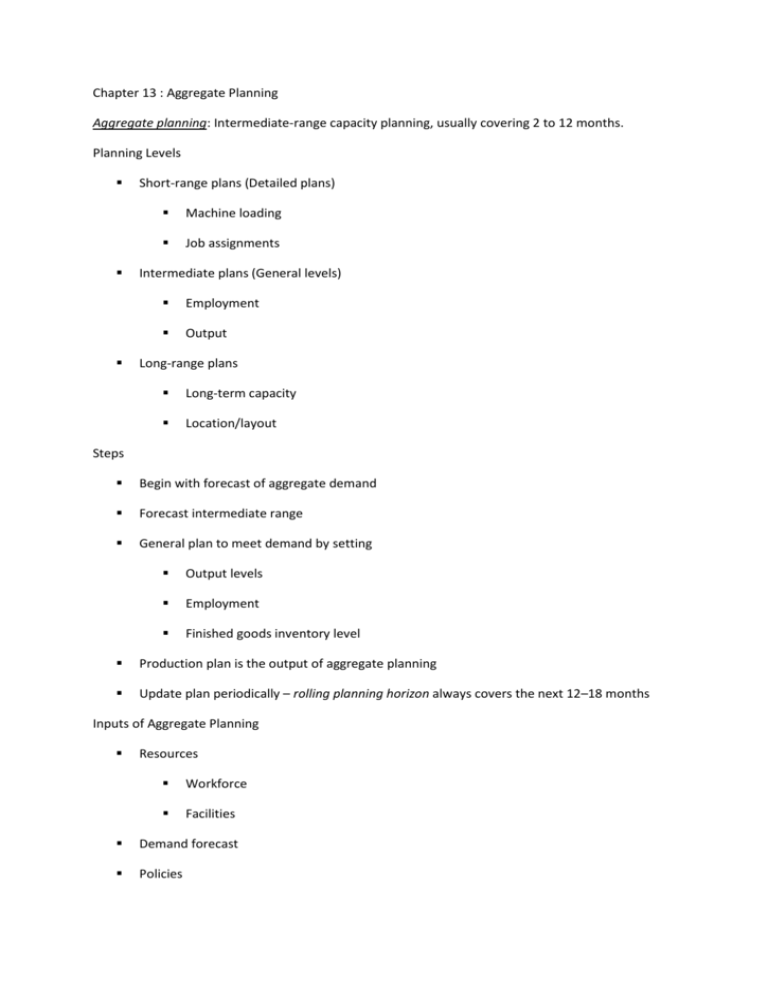

Chapter 13 Aggregate Planning

Coronavirus S Impact On Supply Chain Mckinsey

Metron Capacity Management Capacity Management Guided Practitioner Satnav Capacity Plan 16 Of 17

Could This Be The Easiest Way To Do Team Capacity Planning Kendis

Uninote Ecommerce S3 Eu West 2 Amazonaws Com

Capacity Management At Infrastructure Level Part 1 Virtual Red Dot

5 Best Resource Capacity Planning Template Excel

Project Capacity Planning Template This Excel Sheets Saves You Hours

Level Capacity Plan Approach Ppt Powerpoint Presentation Summary Cpb Powerpoint Shapes Powerpoint Slide Deck Template Presentation Visual Aids Slide Ppt

Capacity Planning Meaning Classification And Its Goals

Level Capacity Plan Level Capacity Plan The Inventory Size Is Varied Keeping The Operation Management

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

1

How To Calculate Production Capacity Of A Factory

Entries For Thursday 25 October 07 Sergio S Blog

Production Planning Meaning Importance Steps Example Mba Skool

Free Capacity Planning Templates Smartsheet

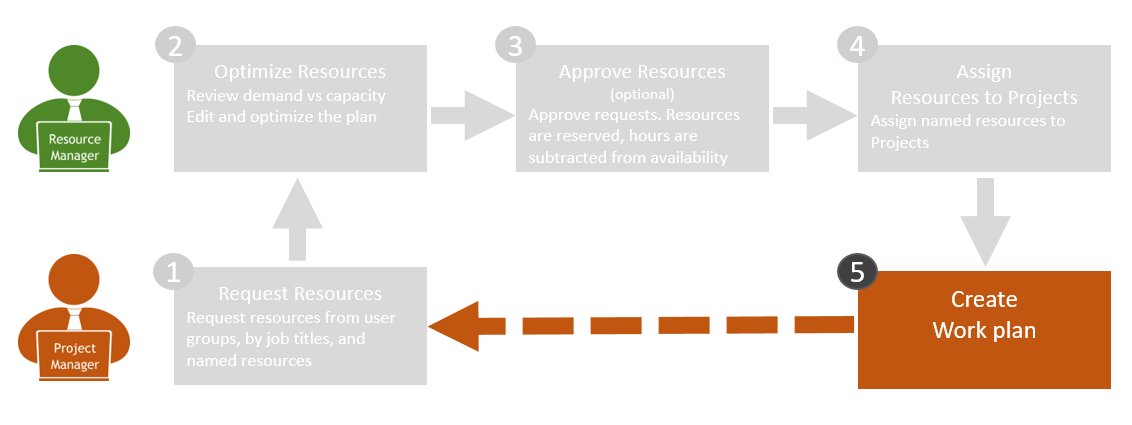

Manage Resource Capacity Planning Scenarios

A Critical Insight To Successful Supply Chain Planning

Capacity Planning Model The Important Inputs Formulas And Benefits Semantic Scholar

Level Capacity Plan Ppt Powerpoint Presentation Pictures Background Cpb Presentation Graphics Presentation Powerpoint Example Slide Templates

Capacity Planning An Overview Sciencedirect Topics

Checklist Capacity Plan It Process Wiki

3 Types Of Capacity Planning Strategies Valq

Set The Team Sprint Capacity In Azure Boards Azure Boards Microsoft Docs

Capacity Planning Template Clicktime

Capacity Planning Everything You Need To Know Opensense Labs

Capacity Planning Template Explore 7 Tips For Effective Planning Project Management Templates

Set The Team Sprint Capacity In Azure Boards Azure Boards Microsoft Docs

What Is Resource Management And Why Is It Important Planview

Free Capacity Planning Templates Smartsheet

Aggregate Planning Chapter 11 Mis 373 Basic Operations Management Ppt Download

0 件のコメント:

コメントを投稿